PLB HDPE TELECOM DUCTS

HDPE PLB Duct Pipes or High Density Polyethylene Permanently Lubricated Ducts are the high flow capacity ducts, which offer a very high quality option for the underground laying of optical fiber cable (OFC). These PLB HDPE Ducts are mainly used for the purpose of laying Optical Fiber Cable as underground conduits. The HDPE Telecom Ducts are manufactured with the high density Polyethylene materials. The material, high density Polyethylene offers a great resistance against the heavy earth loads and is a great in offering the impact and crush resistance. The PLB Duct is manufactured in various colors and sizes. The colors like Blue, Red, Green, Orange, Brown and Grey are some of the prominent colors widely used in the manufacturing of the PLB Duct.

Types of PLB telecom ducts :

- Permanently Lubricated HDPE duct with pre-installed rope

- Permanently Lubricated HDPE Black electric conduits

- Permanently Lubricated HDPE duct with pre-installed cable

- Permanently Lubricated HDPE Duct

- Permanently Lubricated Tracer HDPE duct

- Permanently Lubricated ribbed HDPE duct

-

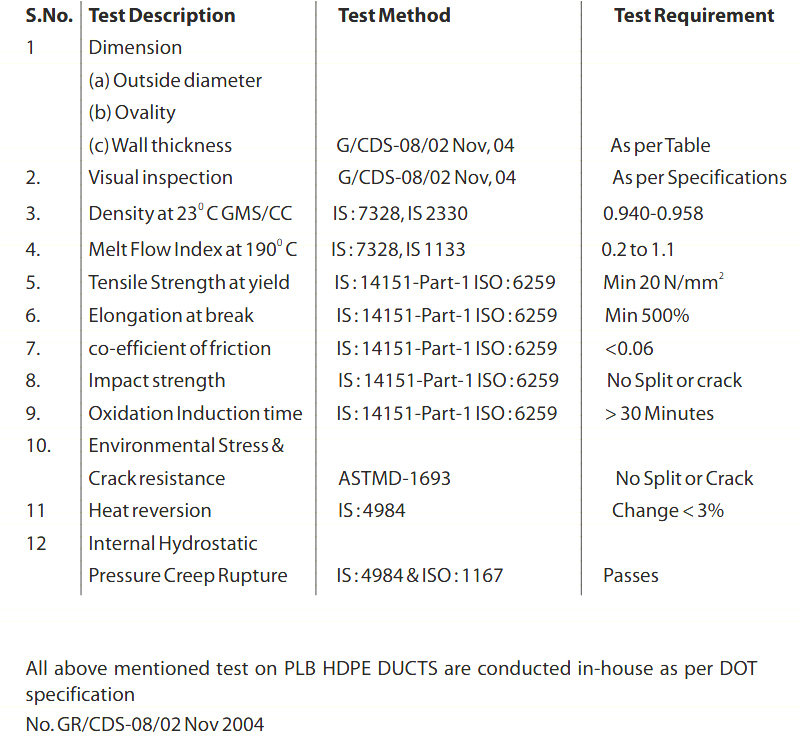

Construction

Shree Salasar Industries HDPE Ducts are formed by co extrusion technique and are used for laying Optical Fiber Cables as underground ducting /conduits.

-

Material

The base raw material being used for the manufacturing Permanently Lubricated Ducts is High Density Poly Ethylene.The grade of raw material is ultra violet grade and is confirming to 15:7328-1 992 & IS :2523 or ISO: 1183 & ISO: 1133 and is designated as PEELA-50T-012 (CACTApproved) and inner layer permanently lubricated material DOW CORNING grade-50MB002.

-

Applications

- Telecommunication

- Computer Network

- Automatic Signaling

- Railways Information Network

- Highways

- Cable Service Providers

- Broad Band networks

- Electric cable installation -

Advantages

- Reduction of stress on cable during installation

- Installation of Longer lengths made feasible

- Negotiations of cable movement through bends and deflections are easier

- Reduction of number of joints and minimizes number of splices

- Faster and easy installation of cable with lesser man power

- Reduction of overall cost of installation, maintenance and future upgrades

- Retains it's properties throughout it's life

- Existing cables can be deployed after de-blowing from the duct

- This does not have toxic and dermatic hazards and is safe handling -

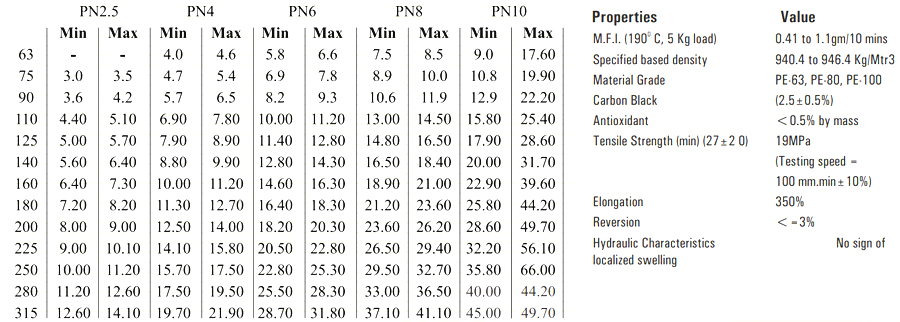

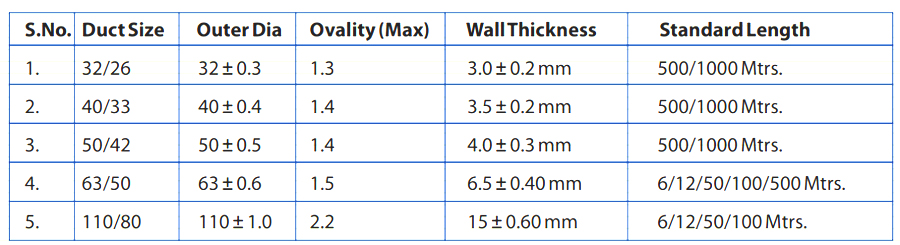

Dimensions

DOT & ISO (All sizes in mm)

-

Properties

-

Associated Accessories & Tools

- Plastic Coupler : To join two duct lengths - airtight and watertight

- End Plug : To seal duct ends prior to the installation of the cable

- Cable Sealing Plug : To seal duct ends after insertion of the cable

- End Cap : Made of hard rubber, fitted on both ends of duct coil after manufacturing

- Duct Cutter : To cut duct cleanly and with square ends

- C Spanner : To tighten plastic coupler -

Wall thickness of pipes for pressure rating of IS :14333-1996