MDPE PIPES

ISO : 4427, ISO : 4437 & IS :14885

Inherent Characteristics of MDPE such as corrosion & crack resistant, tough and flexible makes polyethylene piping systems the most Preferred means for transportation and distribution of water, petrol and natural gases world wide. MDPE Pipes are used for Transportation of Gas as well as for Water all over the world due to its best technical and operational characteristics, We manufacture MDPE Pipes for Gas as well for Drinking Water Supply using virgin Raw material and state of the art machines.its features like weather-proof and long service life.

We manufacture and supply MDPE Pipes (Medium Density Polyethylene Pipes) as per Indian as well as International standards, which can also be customized as per the specifications of our clients. Complying with various standards. In adherence to the set industrial standards, offered pipes are precisely manufactured using better quality required material and advanced machinery at vendors end. Pipes, offered by us are very much cherished by our clients for their finish and elevated durability. Clients can purchase these pipes from us in a range of modified options at competitive prices.

-

Material

The raw material used is medium density poly Ethylene (MDPE). Shree Salasar pipes manufactures pipes in grades PE-80 & PE-100 for gas applications in sizes 20mm to 250 mm (outer diameter) in all pressure ratings. Traditionally these pipes are identified by its color for different uses like blue for water, orange for petrol, and yellow for gas lines.

-

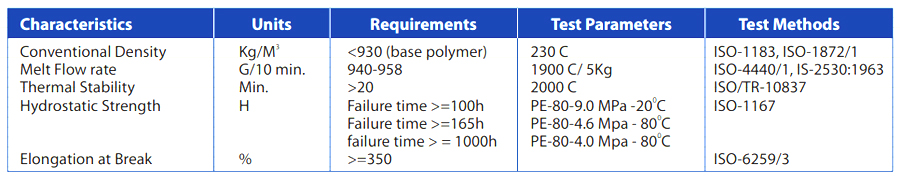

Specifications

SHREE SALASAR manufactures MDPE pipes which confirms to national and international standards as 1504437, 150-44271, ISA 4882,85-728 1, DIW8074/75. Shree Salasar pipes can also be tailor made to meet the specific requirement of individual gas authorities or customers.

-

Salient Features

- Flexible

- Corrosion Resistant

- Fusion Joints

- Light weight

- Crack Resistant

- Homogenous

- Installation

- Easy to Handle

- Leakage free joints & 4 Low installation cost

- Touch and highly reliable in aggressive soils

- High integrity and reliability

- Lighter in weight as compared to metal pipes

- Excellent resistant to subsidence, traffic vibrations

- Point leading and marshy ground -

Physical & Mechnical properties

-

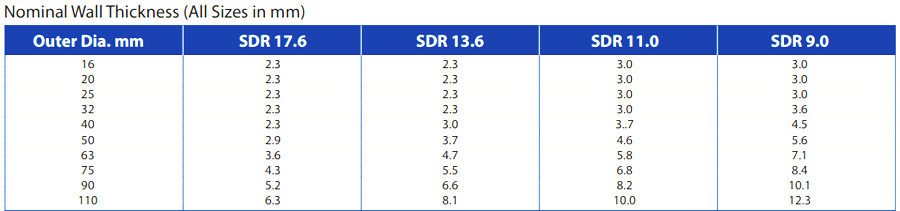

Dimension

-

Properties

- High abrasion resistance.

- High flexibility and impact strength.

- High corrosion resistance, resulting into a longer life.

- Extremely light weight, hence easy to handle, transport & install.

- Excellent water hammer characteristics, helps sustaining pressure surges.

- No exfiltration and infiltration (zero Leak-rate), helps maintaining the quality of fluid being conveyed.

- No trenches needed, resulting into easy and economical installation.

- High UV resistance; virtually maintenance free.

- High resistance to scaling and biological build up.

- High chemical resistance, absolutely inert to any pH value.

-

Applications

Water Supply Systems :

- Transportation and Distribution system.

- House service connection.

- Rural, Municipal Water bodies, SEZ’s, Layout’s, etc.

Agricultural Systems :

- Column piping for Submersible and Jet Pumps.

- Suction and delivery pipes.

- Sprinkler and Drip Irrigation systems.

- Lift irrigation.

- Insecticide spraying.

Industrial/Mining Systems :

- Effluents, chemicals and treated/untreated water disposal.

- Hydro transport system for handling and conveyance of Iron, Coal and Cement slurry in mines.

- For conveyance of edible oil, fruit pulps, juices, milks and other food materials.

- As a ventilation and air conditioning duct.

Environmental Protection :

- Underground drainage and sewerage application/rehabilitation of existing sewer.

- Effluent and waste treatment plants.

- Dust suppression piping systems in cement industry.

- Sand slurry disposal pipes in dredging.

- De-gassing pipes in water effluent marine outfalls.

Others :

- Transportation of chemicals, solids, gas and oils.

- Underwater pipelines/desalination plants.

- Telecommunication cable ducting (PLB Duct.).