HDPE PIPES FOR WATER SUPPLY

IS:4984-2016 (As per ISO 4427-1& 2:2007)

We have developed state-of-the art infrastructure facility that helps in qualitative production of HDPE Pipes ,Our innovative solutions as per the industry standards. Spread on expansive area, our infrastructure assists us in storing, manufacturing, testing and improvising our product range at a smooth and fast pace. Installed with advanced machines and sophisticated technology, our manufacturing unit supports us in customizing the range as per specific requirements of the clients. It also helps to undertake bulk consignments and deliver them in accordance with the industrial standards within given time frame.In line with diverse demands across the globe, we make them available in different sizes, shapes and grades in line with set industry standards for OD 20 mm to 315 mm (In All Grades & Pressure Ratings). To ensure that the customers receive the best quality HDPE Pipes, we test them on several parameters, prior to final dispatch. Buyers can acquire HDPE Pipes at feasible rates, from us.

Construction :

SALASAR HDPE (pipe & Coils) are being manufacture by High Density Polyethylene polymers in all three grades i.e. PE-63, PE-80 & PE-100 conforming to 15:4984-2016 with latest amendments.

Size Range

• Size Range from 20 mm to 500 mm OD

• Nominal Pressure from PN -2 To PN -20

• The Standard Dimension Ratio From SDR-41 to SDR-6

• PE Grades : PE-63, PE-80 & PE-100

| 20 mm to 50 mm | 100m, 200m, 300m, 500m, & 1000m |

| 63 mm to 75 mm | 100m, 200m & 300m coils |

| 90 mm to 110 mm | 100m / 150m coils & Straight length of 6m to 12m |

| 125 mm to 500 mm | In straight length of 6m / 12m |

| Condition | New |

| Material Grade | PE100, PE80, PE63 |

| Pressure Rating | PN-2.5, PN-4.0, PN-6.0, PN-10, PN-12.5, PN-16.0 |

-

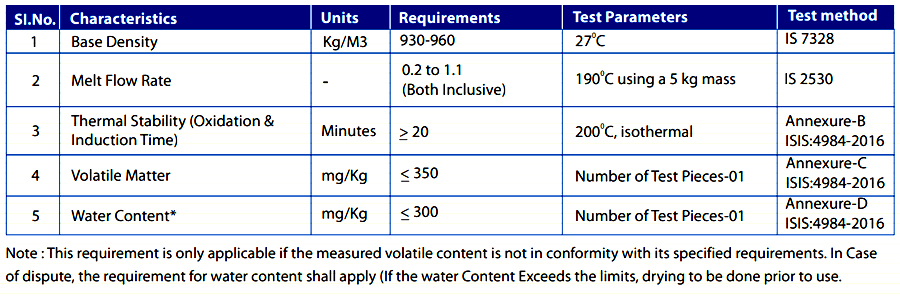

Characteristics of PE Resin as Granules (Table)

-

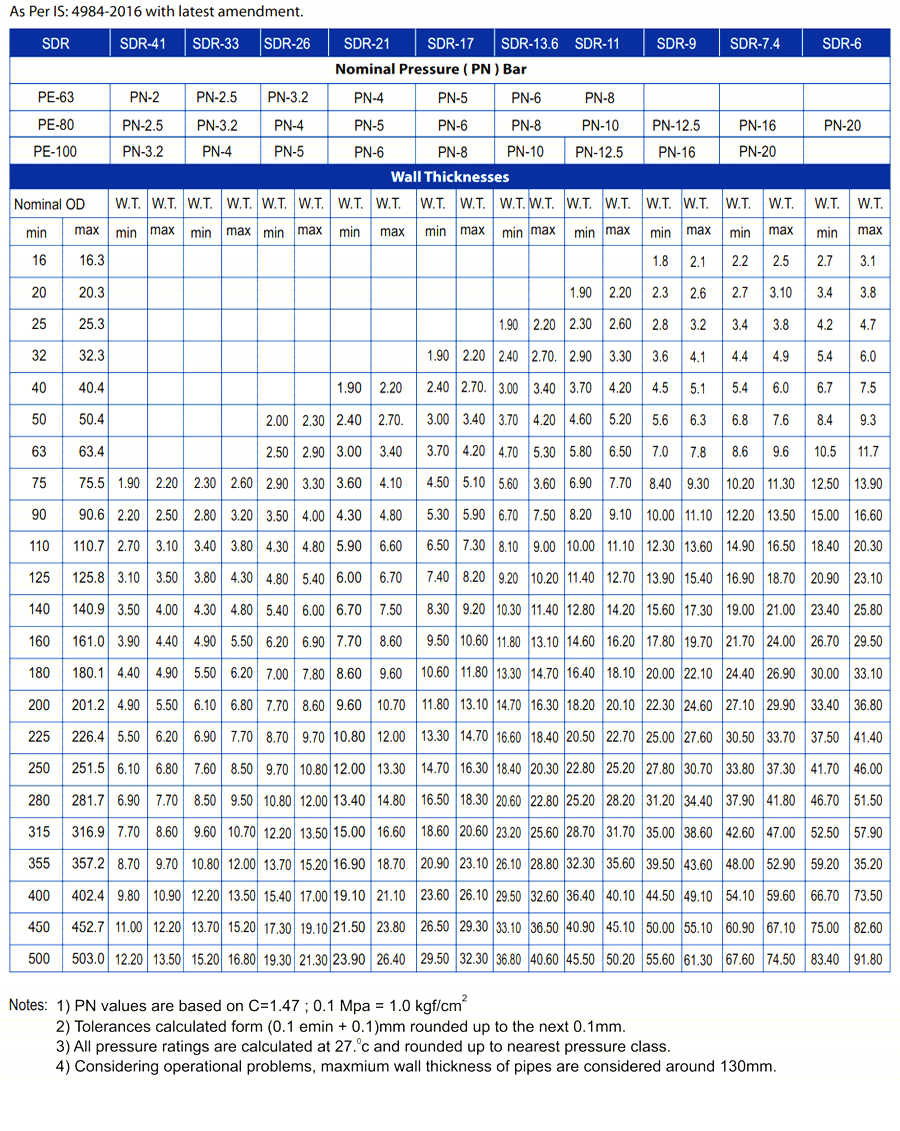

Standard dimension ratio (SDR) and corresponding wall thickness of pipes

-

Salient Features

- Resistance to chemicals -Exceptional resistance to all external & internal corrosion.

- Resistance to electrolyte corrosion.

- Will not rust or rot.

- Welded joints speedup installation trench widths reduced which leads to saving in the cost of excavation and back filling.

- Smooth bore provide less head loss.

- Flow resistance is approximately 30 % less than that conventional pipe, permitting the use of a smaller bore pipe for a given rate of flow.

- High impact strength.

- High reliability and proven service performance.

- Greater flexibility, light weight, easy &economical installation.

- Very good thermal insulation due to low thermal conductivity.

- Flame resistance classify the material as self extinguishing according to test standard employed.

- Perfect stability f material obviates the risk of ageing and ensures long service life. -

Properties

- High abrasion resistance.

- High flexibility and impact strength.

- High corrosion resistance, resulting into a longer life.

- Extremely light weight, hence easy to handle, transport & install.

- Excellent water hammer characteristics, helps sustaining pressure surges.

- No exfiltration and infiltration (zero Leak-rate), helps maintaining the quality of fluid being conveyed.

- No trenches needed, resulting into easy and economical installation.

- High UV resistance; virtually maintenance free.

- High resistance to scaling and biological build up.

- High chemical resistance, absolutely inert to any pH value.

- Available in suitable coils of 50m to 1000m ( Depending on Pipe OD) as well as in straight lengths of 5 to 12 meters thus minimizing joints and making laying easier and quicker.

- Smooth inner surface prevents growth of bacteria hence makings pumping easier and faster, which leads to significant energy savings. -

Applications

Water Supply Systems : These pipes are used for water mains & services and for water supply over & under ground and, both inside & outside building.

- Transportation and Distribution system.

- House service connection.

- Rural, Municipal Water bodies, SEZ’s, Layout’s, etc.

Agricultural Systems :

- Column piping for Submersible and Jet Pumps.

- Suction and delivery pipes.

- Sprinkler and Drip Irrigation systems.

- Lift irrigation.

- Insecticide spraying.

Industrial/Mining Systems :

- Effluents, chemicals and treated/untreated water disposal.

- Hydro transport system for handling and conveyance of Iron, Coal and Cement slurry in mines.

- For conveyance of edible oil, fruit pulps, juices, milks and other food materials.

- As a ventilation and air conditioning duct.

Environmental Protection :

- Underground drainage and sewerage application/rehabilitation of existing sewer.

- Effluent and waste treatment plants.

- Dust suppression piping systems in cement industry.

- Sand slurry disposal pipes in dredging.

- De-gassing pipes in water effluent marine outfalls.

Others :

- Transportation of chemicals, solids, gas and oils.

- Underwater pipelines/desalination plants.

- Telecommunication cable ducting (PLB Duct.).