HDPE PIPES & COILS

IS : 4984-2016

We are counted amongst the reckoned names in the industry offering varied range of HDPE Pipes & Coils that is highly acclaimed among the clients for its high quality and optimum strength. These products are durable in nature and can be easily installed as per the requirement of the clients. We are offering these pipes at affordable price within the stipulated period of time. It is especially designed for the production of larger diameter & thick walled pipe, but can be processed for the whole range of diameters. It also shows excellent resistance to rapid crack propagation and slow crack growth.

Recommendations

| Depth of the bore | Pressure Class |

| Up to 55 Mtrs | 4.0 kg/cm2 |

| Up to 90 Mtrs | 6.0 kg/cm2 |

| Up to 140 Mtrs | 10.0 kg/cm2 |

| Up to 170 Mtrs | 12.5 kg/cm2 |

-

Materials

It is made of either of three grades of High Density Poly Ethylene polymers. i.e PE-63, PE-80 & PE-100

-

Product Range

These HDPE pipes are available in sizes 20 mm to 315 mm in pressure rating of PN-2.5, PN-4.0, PN-6.0, PN-8.0, PN-10.0, PN- 12.5 & PN-16.0 in all three grades PE-63, PE-80 and PE-1 00

-

Applications

Effluent and Waste Water Disposal : Effluents of varied chemical compositions can be effectively disposed of using Shree Salasar HDPE pipes & coils, with the aid of the latest know-how on piping engineering, pipelines for waste collection and disposal in chemical industry. Longevity of Shree Salasar pipes under such application would rate the best amongst the conventional pipe even under critical service conditions.

Domestic Gas Distributions : Earlier, engineers always carried a psychological fear in using HDPE pipes rather plastic pipes for conveyance of inflammable gases. However experiments and extensive trials proved these fears totally wrong and heavy established excellence of performance of HDPE pipes for conveyance of all type of combustible gases. Experiments have also proved that the permeable losses are insignificant in regard to safety and environmental impact.

Submarine Pipelines: One of the most important applications where all salient features of Shree Salasar pipes prominently figure out is for under water pipelines. Shree Salasar pipes have been successfully laid for under water river crossing, creek crossing, marine out-falls and for brine intake lines in the open sea. Hazardous chemical effluents and radio active wastes are being harmlessly disposed into deep sea through Shree Salasar pipes with substantial cost savings. Schemes which would have been dropped due to economical un-viability have been made feasible with Shree Salasar pipes. -

Properties

- Economical than traditional pipe material

- Resistance to chemicals- Exceptional resistance to all external and internal corrosion

- Resistant to electrolytic corrosion

- Will not rust or not

- Welded joints speedup installation-Trench widths reduced which leads to saving in the cost of excavation and back filling

- Light weight - One sixth of the weight of steel. Low specific gravity giving an outstanding light weight product for easy transportation, handling, fitting etc

- Very good thermal insulation due to low thermal conductivity

- Smooth bore provided less head loss

- Flow resistance is approximately 30% less than that of conventional pipes, permitting the use of a smaller bore pipe for a given rate of flow

- Perfect stability of material obviates the risk of ageing

- Total neutrality to products conveyed

- Flame resistance classifying the material as self extinguishing according to test standard employed

- Low maintenance cost

- Easy to install

- Longer life than G.I, M.S, cement and other pipes -

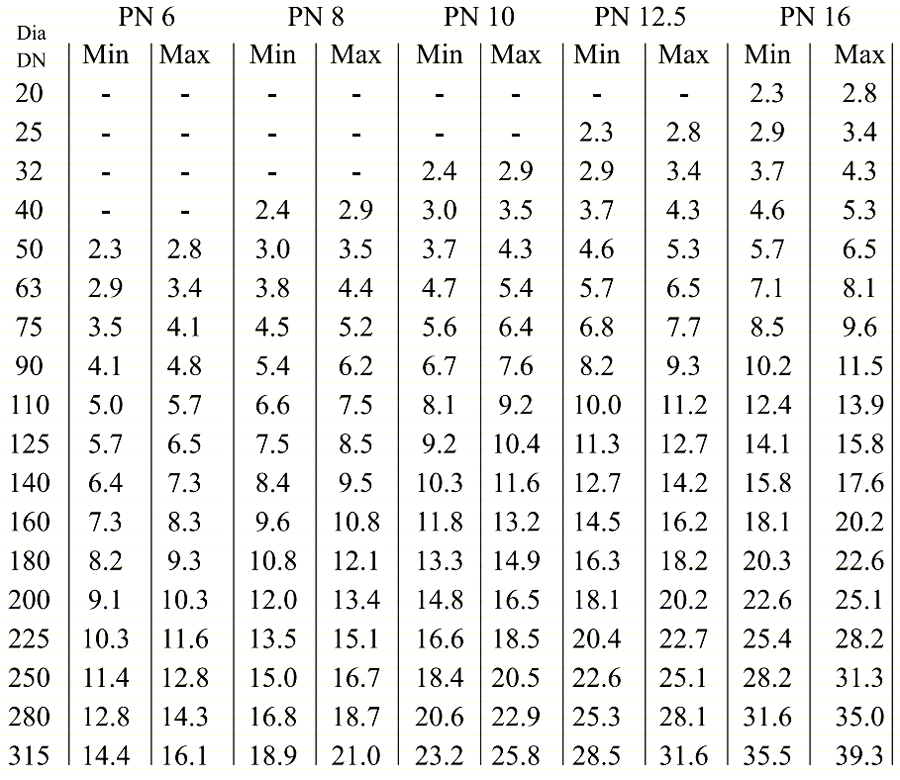

Wall thickness of pipes (PE-63) for pressure rating of IS:4984

-

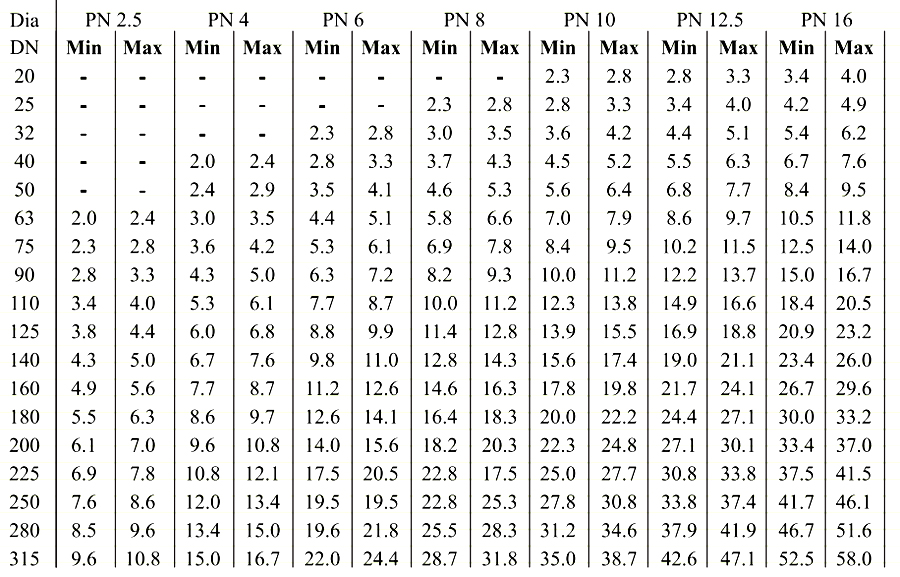

Wall thickness of pipes (PE-80) for pressure rating of IS:4984

-

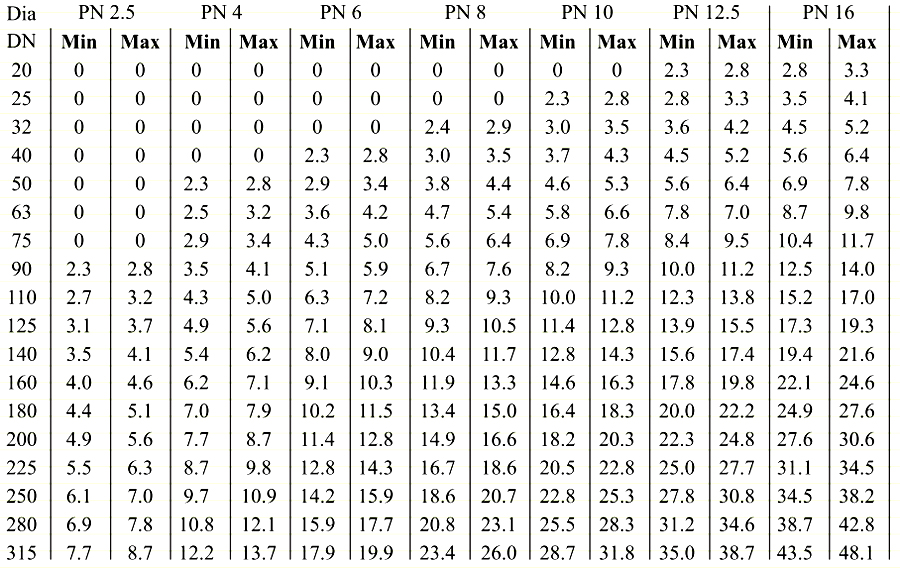

Wall thickness of pipes (PE-100) for pressure rating of IS:4984